22 Oct 2004 Fuel Pumps

Having a closer look at the fuel pumps, and I’m still full of questions. Jan told me they are airtex E8228 fuel pumps. http://www.airtexproducts.com/ is their website, but it is basically useless. No info.

Is there a check valve in the exit of this fuel pump? This photo seems to show one:

I found out from Jan that yes, this is a check valve at the fuel pump outlet.

There is some kind of spring in the inlet as well:

The fuel pumps have hose barbs on them, requiring rubber hoses.

I still need to decide on an intake fuel filter. I’m leaning heavily towards the Aeromotive #12302 fuel filter, which has this information on their web site:

Pro Series Fuel Filter featuring 100 micron cleanable, stainless steel element, massive -12 AN inlet and outlet ports, and the Pro Series electroless nickel-silver finish. 7″ long X 2.5″ diameter. Flows 2,000 lb/hr with a pressure drop of less than 0.15 PSI! Perfect for inlet protection of expensive, high flow racing fuel pumps. About 130 USD.

Of course the major problem is the AN-12 ORB port on the filter, which will require some serious adapting to get it down to the miniscule AN-6 fitting I have on my intake. I might upgrade my intake to AN-8.

I also may just use the Aeromotive #12304 fuel filter:

Billet, in-line housing with -10 AN ports and hi-flow 100-micron (coarse) cleanable, stainless steel element. Recommended before fuel pump. 5″ long X 2″ diameter. Flows 2,000 lb/hr with a pressure drop of less than 0.5 PSI. About 90 USD.

A 0.5 PSI pressure drop at 2,000 lb/hour would mean that for our application, 43 gallons / hour (258 lb/hour), we would have a pressure drop of about .0645 PSI, assuming the pressure drop is linear with mass flow. Not sure about that.

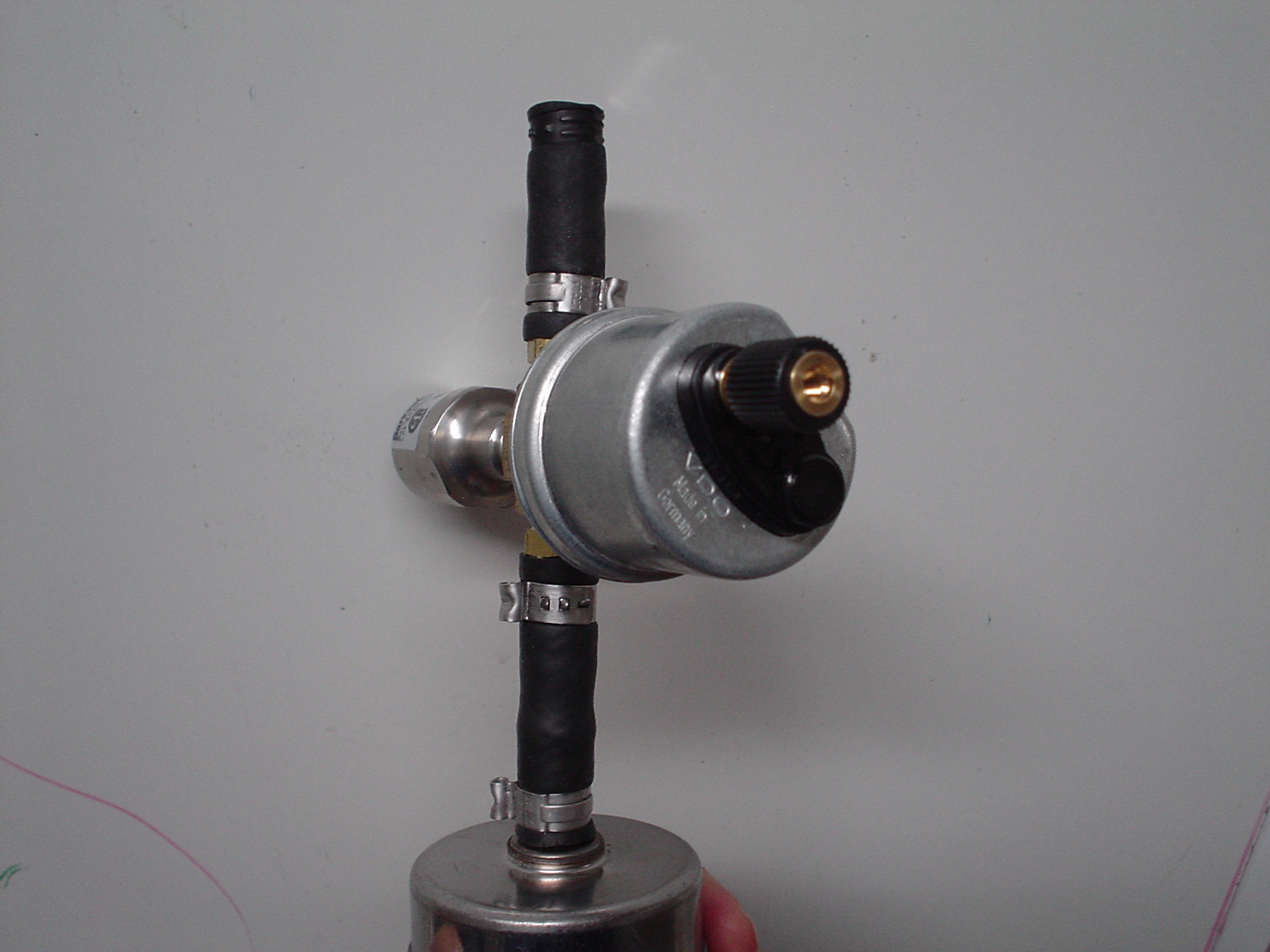

Here are a couple of other important gizmos.

This “Barksdale” device is the pressure transducer that allows for the automatic switchover of the fuel pumps to the backup, in case the pressure drops too low.

This VDO device is to send the fuel pressure up to the EIS for display. If it is installed using rubber hoses, the body of the device must be grounded – typically using a hose clamp connected to a grounding wire.

Sorry, the comment form is closed at this time.