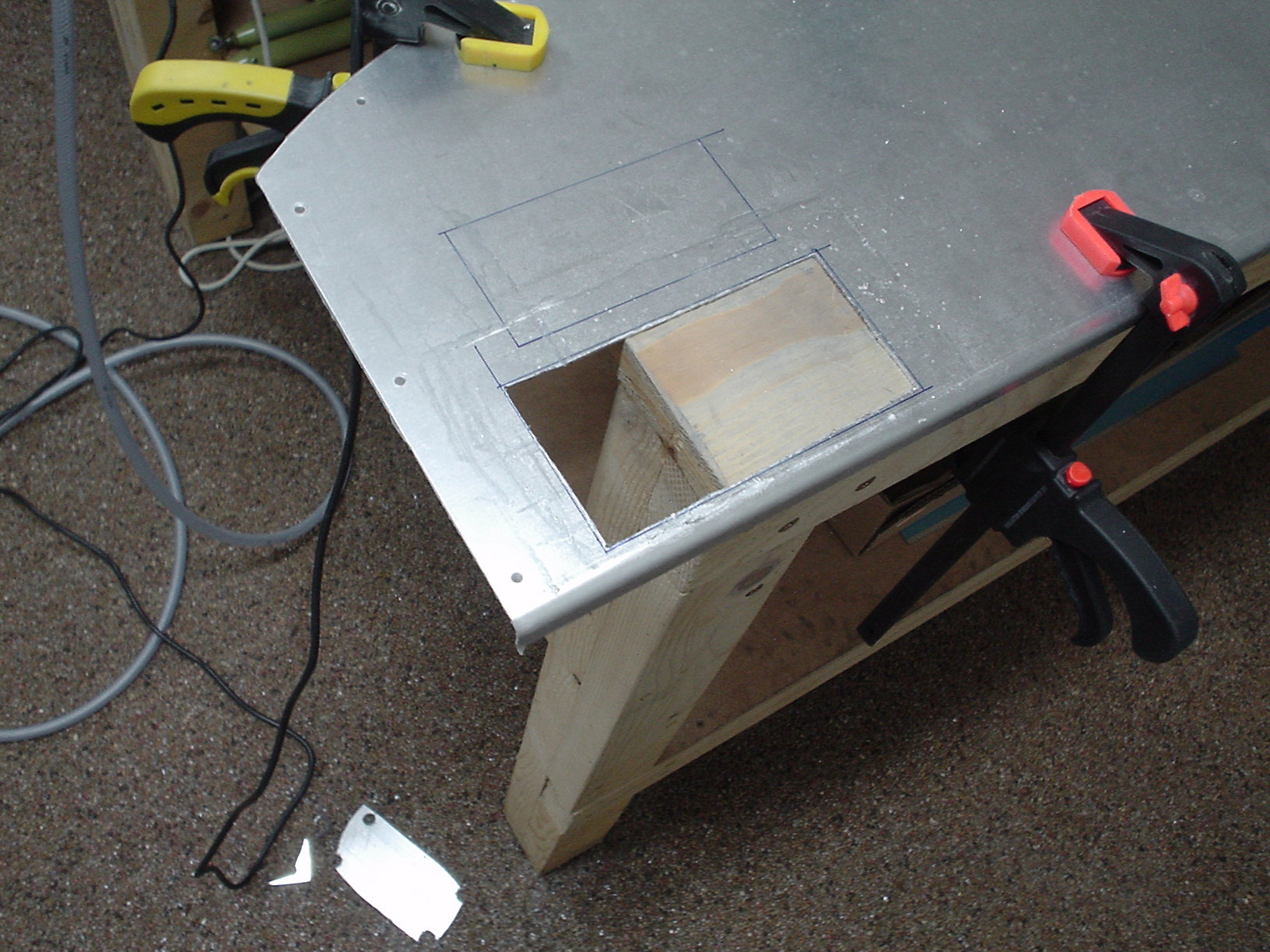

03 Nov 2004 Cutting first hole in the instrument panel

I decided it was time to try my hand at cutting some holes in the instrument panel. I’ve heard it is really hard, and a lot of people have outsourced this to people who take CAD drawings, and watercut the panel.

I figure if I have to do this, or decide to do this, I’ll get a new panel from Van’s and have it shipped to the machine shop. So, I feel free to experiment with this panel. Either it will turn out ok, and I’ll save a lot of money, or it won’t.

I decided to start with the “radio” rack – these are the big square holes. Probably easier than the round holes, and will provide me with some more work in creating the rack.

First holes cut with the unibit.

Rough cutout with a jig saw.

Bit more cleanup with the jig saw.

Filing down the edges. Used a file, and a ShurBrite wheel to get it into shape.

Looking pretty good here, about to claim victory on this one. Now onto the “rack”.

Sorry, the comment form is closed at this time.